Character:

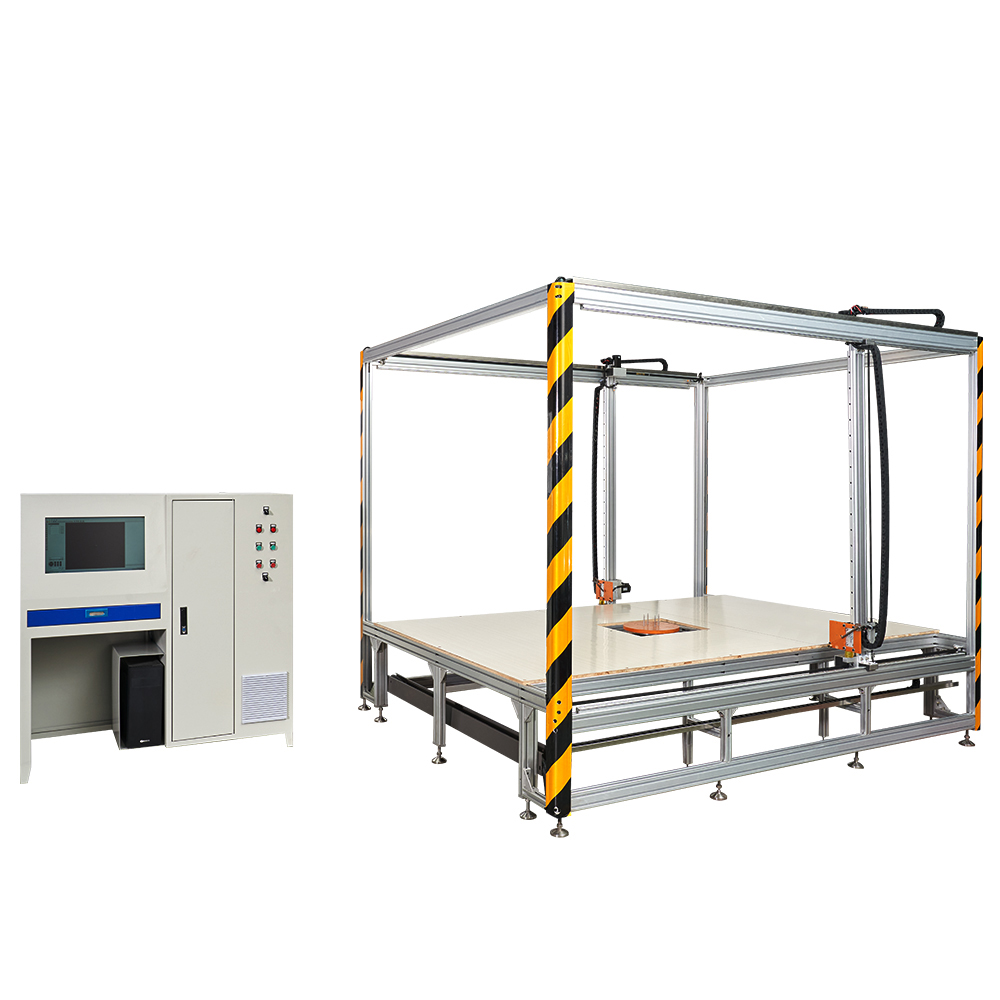

– All procedures are controlled by Touch screen & PLC, all parameters can be revised in touch screen

– All material connected with EPS resin in expansion Chamber are made of SUS 304 Stainless steel

– High density Rock wool used for insulation layer to reduce temperature undulate & steam consumption.

– Steam system controlled by origin Japanese Pressure Reduction Valve, Brand “Yoshitake” GP-2000

– EPS Resin weight in Each cycle are controlled by accurate weight sensor for first expansion .

– Second Expansion is available for lower density

– Stable pressure & stable temperature insure density tolerance within 5 %

– maintenance stair and protective fence on the top for safety and easier maintenance

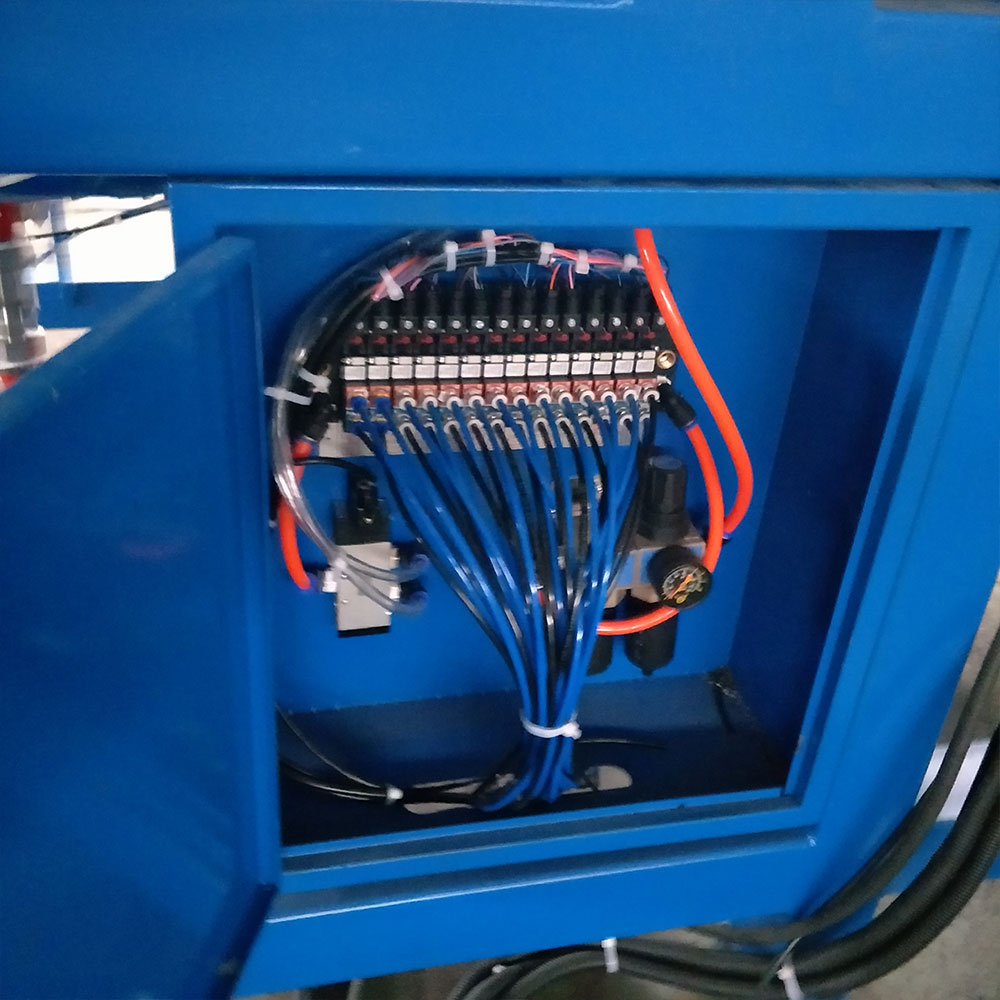

-Control panel declaration:

i)All electronics are brand Schneider, Air condition is equipped for control box .

j)Taiwan Delta PLC and Taiwan weiview touch screen (10.1”)

k)pneumatic valves are brand Burket (Germany)

l)one level photo sensor for double safety

m)Use vibration level sensor to control heating of expansion .

F ) Note:

Density: 8-9 g/l for china and taiwan EPS raw material (Zkf301 or ZKF302) sabic F760 with double expansion

9-10 g/l for sabic EPS raw material (F650)