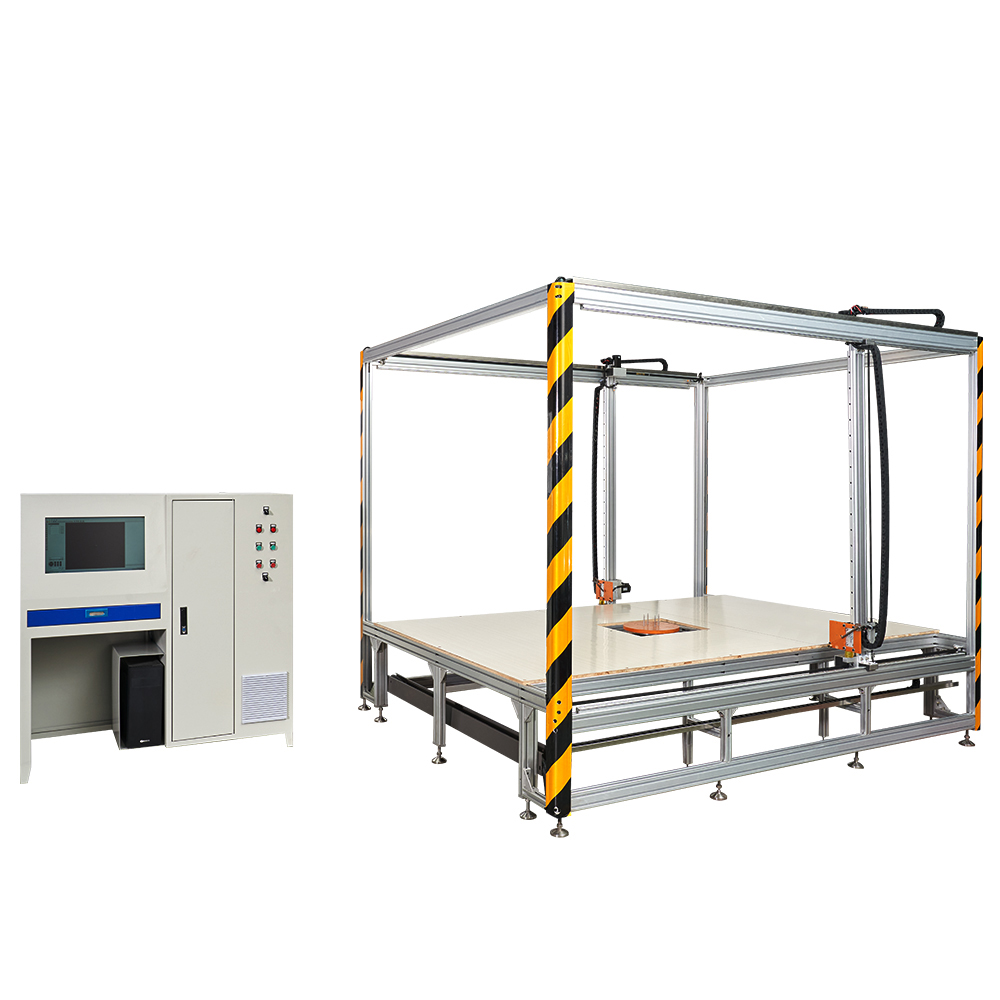

Machine features:

1. Touch Screen Panel –Schneider (France)

2. PLC System –MITSUBISHI(Japan)

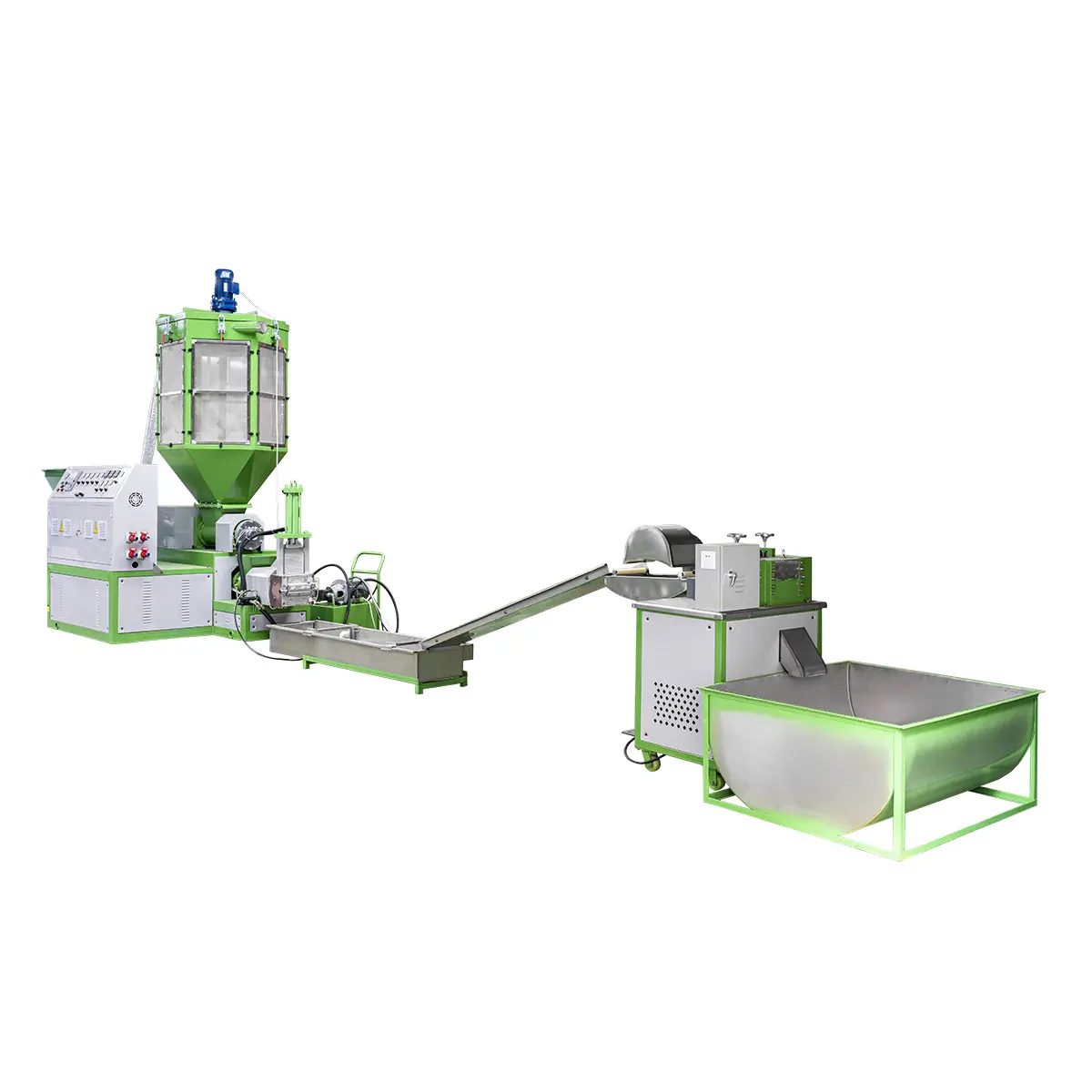

3. Steam regulator (Japan) GP2000 type

4. Material transfer with screw conveyor and weighing scale.

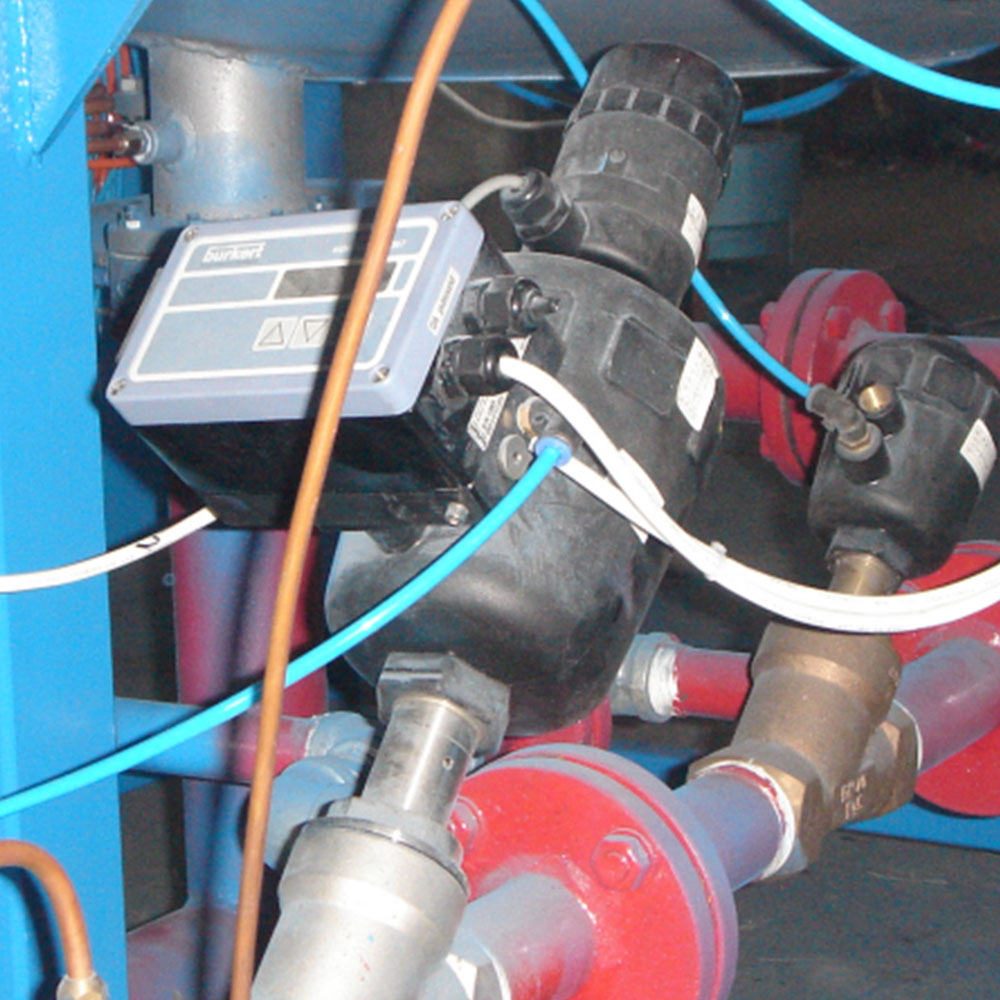

5. Air solenoid valve – Burkert (Germany)

1.3 Character

– Three Safety features and protective fence on top

– All procedures are controlled by Touch screen & PLC, all parameters can be revised in touch screen

– All material connected with EPS resin in expansion Chamber are made of SUS 304 Stainless steel

– High density Rock wool used for insulation layer to reduce temperature undulate & steam consumption.

– Steam system controlled by origin Japanese Pressure Reduction Valve, Brand “Yoshitake” GP-2000

– EPS Resin weight in Each cycle are controlled by accurate weight sensor for first expansion .

– Stable pressure & stable temperature insure density tolerance within 3%

– with multi- exhausting valves to control chamber pressure precisely and less steaming consumption

-Control panel declaration:

a)All electronics are brand Schneider, Air condition is equipped for control box .

b)Japan Mitsubishi PLC and Taiwan veinview touch screen

c)Pneumatic valves are brand Burket (Germany)