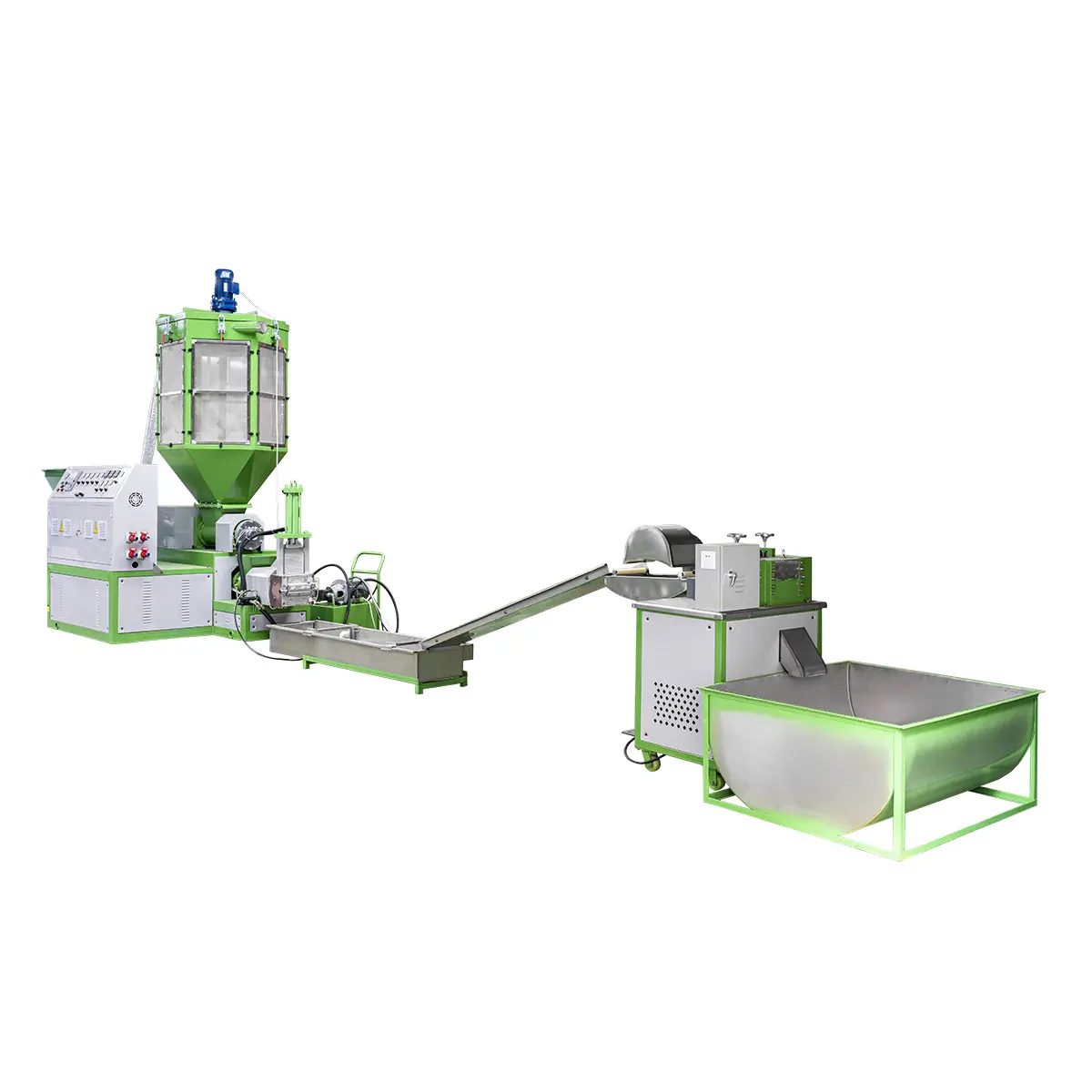

GB-SPR-L Crushing & Dedusting Integrated Recycling Machine is new design for EPS scraps recycle, consists of a crusher, a dust collector, an intergrator and a mixer.This machine havelots of strong points, like higher capacity, less dust rate, as well Proportional mixing. With this recycle system, The waste EPS craps will become every clean and qualified beads.Which will be mixed with newEPS expansion beads again for EPS block production.

—-

ntroducing our Innovative EPS Crushing and Dedusting Integrated Machine

Are you in search of a cutting-edge solution for EPS recycling and waste management? Look no further than our state-of-the-art EPS Crushing and Dedusting Integrated Machine! Engineered to address the growing need for efficient and eco-friendly EPS disposal, our machine offers a comprehensive and sustainable approach to EPS crushing and dedusting.

Key Features:

Superior Crushing Capability: Our machine is equipped with advanced crushing technology that ensures efficient and thorough crushing of EPS materials, reducing them to smaller, more manageable sizes.

Effective Dedusting System: With a powerful dedusting system in place, our machine effectively removes dust and impurities from crushed EPS, ensuring a cleaner and safer working environment.

Compact and Easy to Use: Designed for user convenience, our machine boasts a compact footprint and user-friendly controls, making it easy to operate and maintain.

Energy Efficient: Our EPS Crushing and Dedusting Integrated Machine is designed with energy efficiency in mind, helping you reduce operational costs while minimizing your carbon footprint.

Benefits:

Sustainable EPS Recycling: By investing in our machine, you are actively contributing to the promotion of sustainable EPS recycling practices, helping to protect the environment and conserve valuable resources.

Cost Savings: With its efficient operation and energy-saving features, our machine allows you to achieve significant cost savings over time, making it a financially viable investment for your business.

Enhanced Workplace Safety: The dedusting system of our machine helps create a cleaner and healthier working environment by reducing airborne dust particles, promoting better air quality for your workers.

Experience the Next Generation of EPS Recycling Solutions with our EPS Crushing and Dedusting Integrated Machine. Contact us today to learn more about how our innovative machine can revolutionize your EPS waste management process!