The machine will crush EPS XPS scraps into smaller pecs. Then melting it by first screw, extruded into PS noodle by second screw, after that, water cooling, De-water and cut into PS granules. Those PS granules is 100% raw material for PS cornice, photo frame, XPS panel and PSP fast food container production line. Directly turn EPS, XPS scraps into PS granules by this single Pelletizer machine.

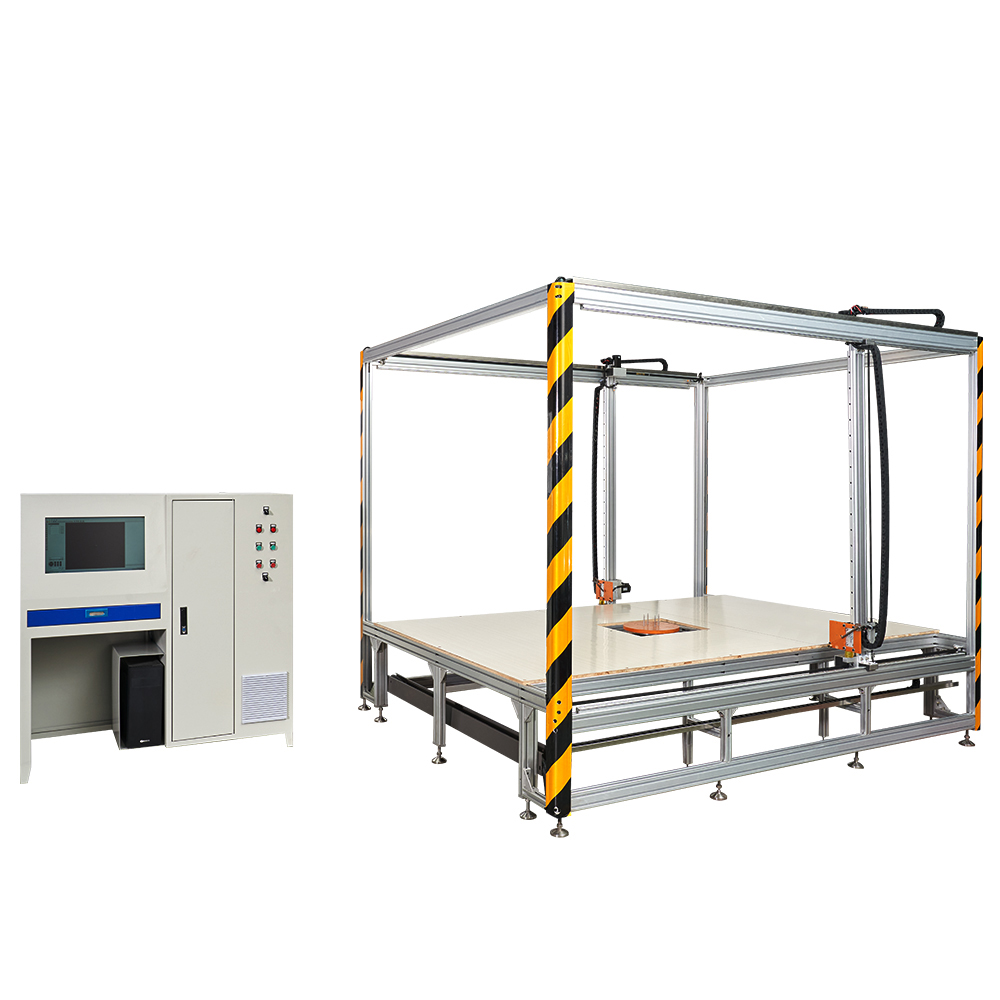

EPS Pelletize Machine

Video

Main Features

- From foam crushing hot melting, extrusion, cooling, pelletizing, an entire production line, to turn the waste foam into PS granules.

- Two stage screw, one stage screw hot melt, two stage screw extrusion, equipped with automatic hydraulic system for filter net change, making the equipment not easy to break wires, and the equipment can produce continuously.

- An efficient crushing system is equipped with alarge silo,can variable frequency feed, greatly improve the production efficiency, while ensure sufficient and stable feeding, make the extruded particles uniform.

- The secondary screw is made of 38CrMoAl material, and the primary and secondary screws are hardening and tempering to ensure their service life.

- All electrical equipment adopts Schneider brand, and all components adopt aviation plugs, with stable quality and convenient on debugging and installation.

Main Technical Parameters

| one stage Screw and barrel | made of 45# STEEL , inlet mouth is coverd special alloy (screw dia.¢160,long dia.ratio 160*200*640 ) |

| Motor | 15kw-4p general motor |

| Mould | Round Mould head |

| Heat loop | stainless steel cuprum |

| Gear box | ZLYJ133strong hard-teeth surface , made of top grade special alloy |

| Screw and barrel | made of 38CrMoAl , inlet mouth is coverd special alloy(screw dia.¢90,long dia.ratio 90*130*850 ) |

| Motor | 4kw-4p timing motor |

| Mould | Hydraulic Mould head |

| Heat loop | stainless steel cuprum |

| Control box | digital meter |

| Water tank | water cooling 2000 mm |

| Granule cutter | ¢100*100 ,1.5KW-4P timing motor |

| Material receiver | steel . |

| CRUSHING&BAITING SYSTEM | foam crusher : suction blower , suction pipe |

| Output | 50-70 kg/h |

| Total Power | 27 Kw 380 V, 50HZ, 3 PH |

| Total weight | 1700kg |

| Required Area | 6 x 2m x 4.5m |

Leave Your Message

For more information about any of our services, don’t hesitate to get in touch. Our team is always happy to provide information about EPS Industry products.