Character:

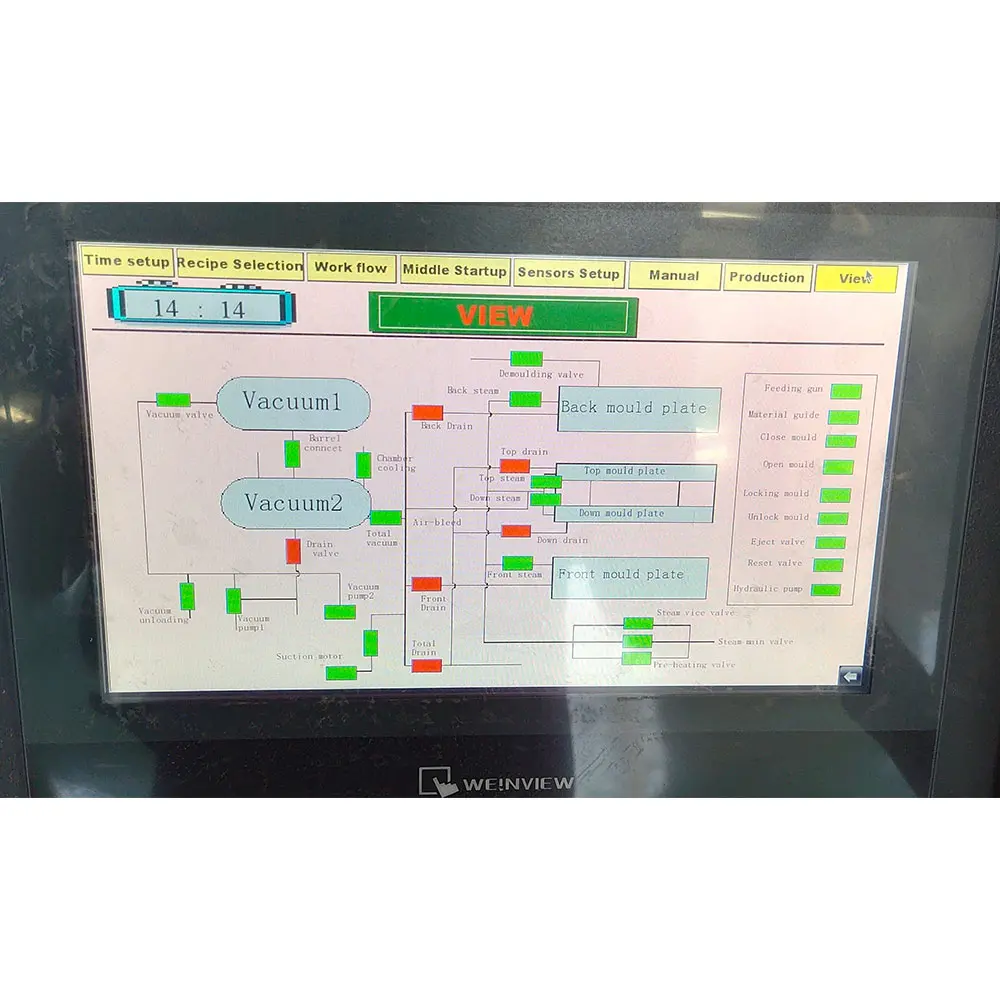

– All procedures are controlled by HMI & PLC, all parameters can be revised in HMI with easy operation

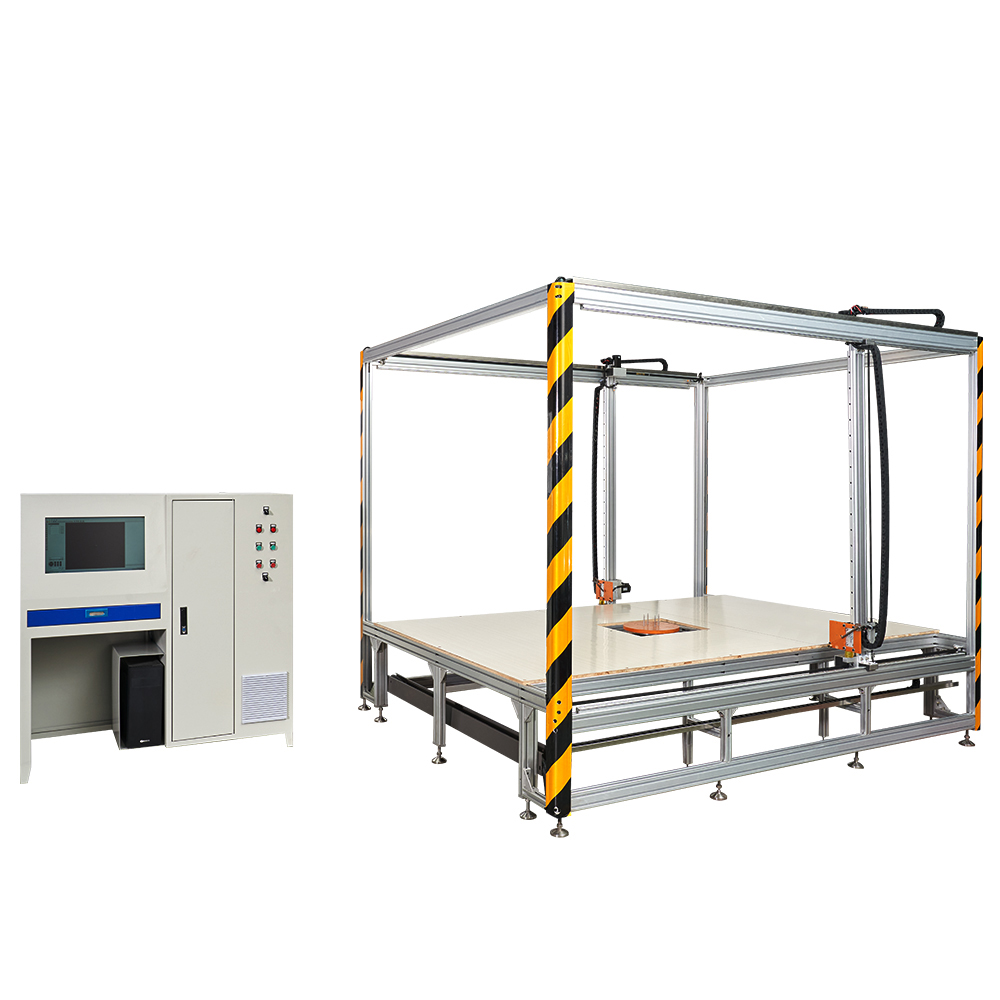

– State standard Q235B Profile steel are used for block mould frame.

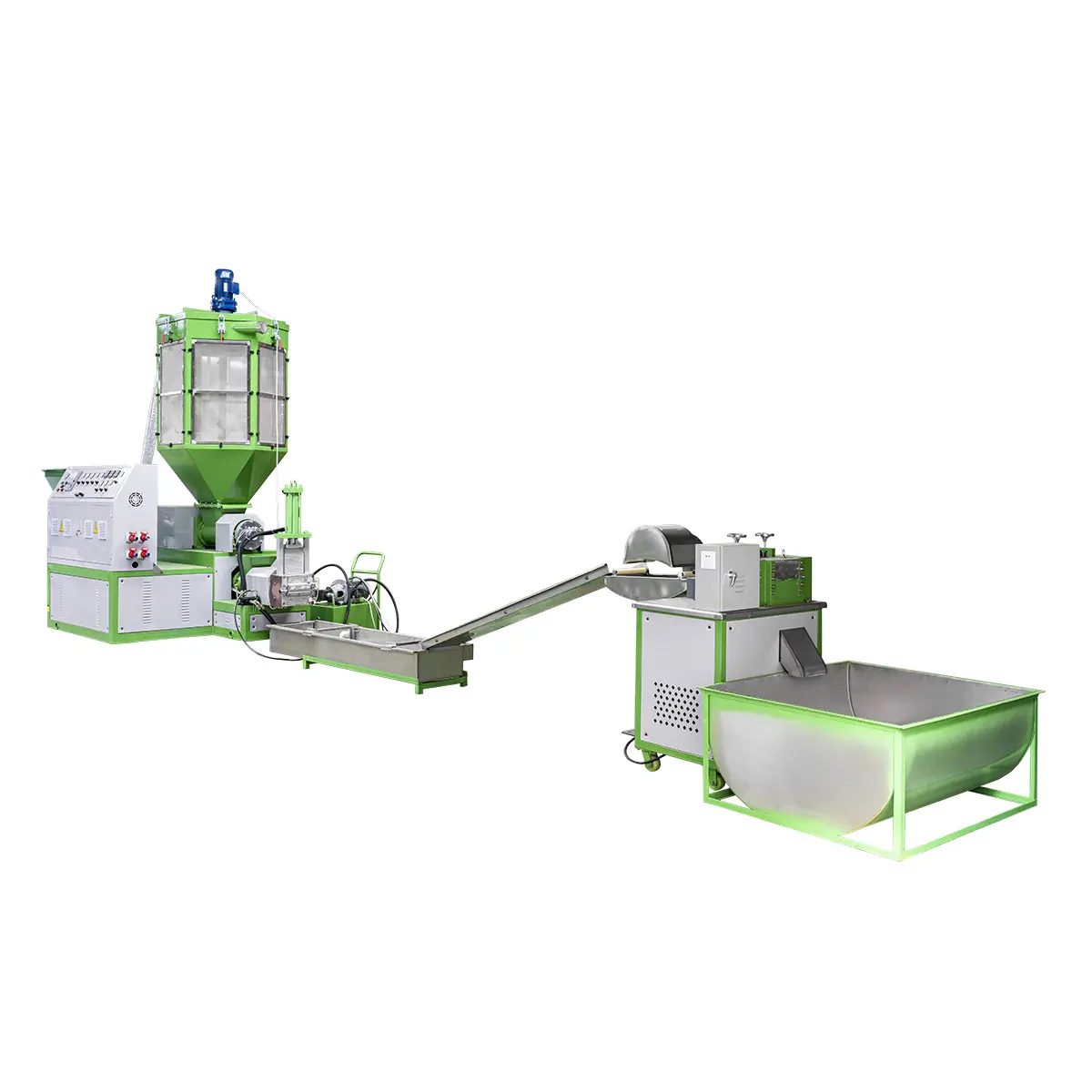

– State standard LY12 aluminum is used for steam chamber, thickness 5mm

– All electronics are brand Schneider, Pneumatic valves brand Airtec.

– Yuken brand hydraulic controls block ejection, open & close door, lock & unlock door.

– vacuum and air blower filling mode, 4 unit filling guns from back side and 4 unit filling guns from top

– outside pipe system for more even steam.

– Japanese steam reducer DN100 for stable steam

– Foam pressure sensor control cooling for automatic process. The foam pressure setting can be adjusted in touch screen. Which is more accurate and easy to adjustable.

– all butter fly valve will be used this fan shape head butterfly valves.

– set protection system for suddenly power off, and inter-middle restart process.