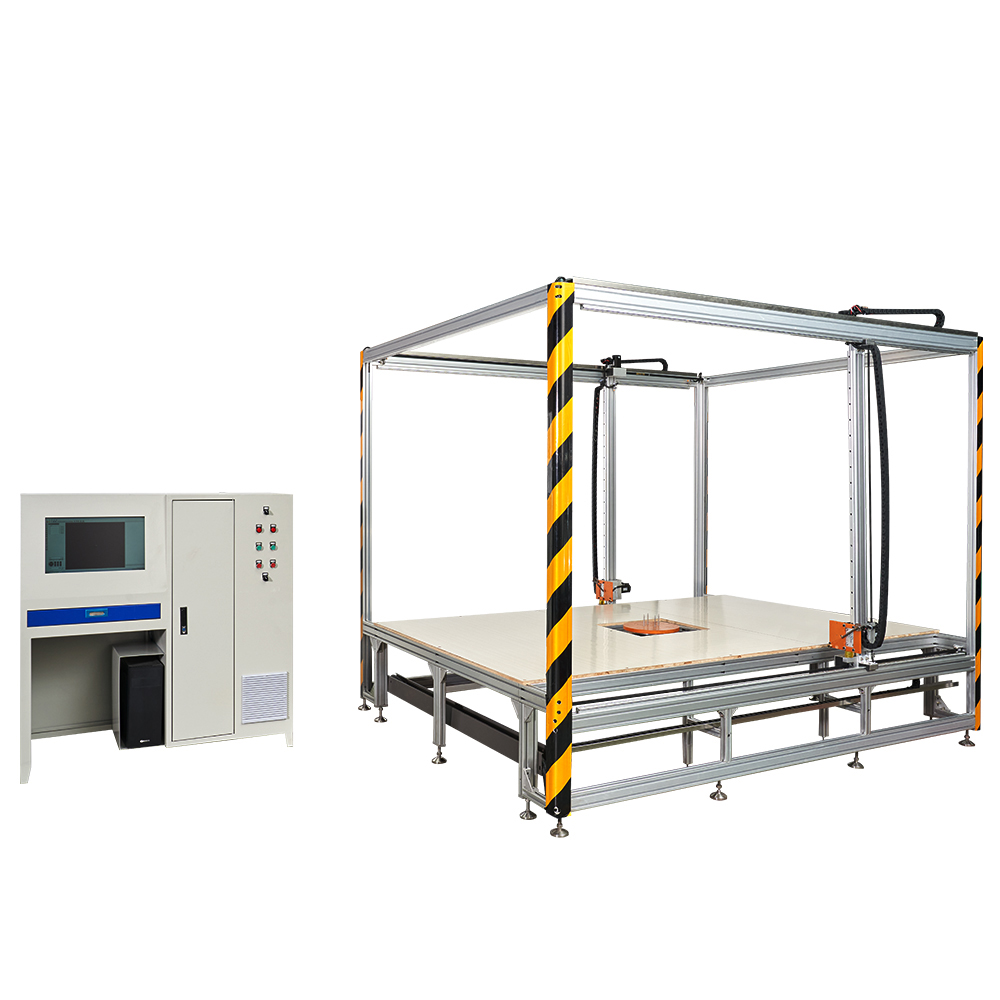

GB-SPZ1400-1750PT EPS full-automatic foam forming machine adopts PLC and touch screen control, hydraulic movement drive, precise control of the whole process of feeding, steam heating, water and vacuum cooling, de-mould and ejection. The equipment considers stable mechanical structure,precise steam heating, and efficient vacuum cooling, greatly improve the molding speed of the equipment and reduce steam consumption. In addition, equipment operability and maintenance safety are also integrated into the design, making this machine the first choice of EPS foam packaging and molding plant.

EPS Shape Molding Machine

Video

Main Technical Parameters

| Mould Dimension | mm | 1400×1200 | 1600×1350 | 1750×1450 | |

| Product Dimension | mm | 1200×1000 ×330 | 1400×1100 ×330 | 1550×1200 ×330 | |

| Minimum Mould Thickness | mm | 220 | 220 | 220 | |

| Stroke | mm | 210-1410 | 210-1410 | 210-1410 | |

| Speed | mm/sec | 210 | 210 | 210 | |

| Steam | Entry | / | DN100 | DN100 | |

| Consumption | Kg/cycle | 6-8 | 7-9 | 7-10 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | |

| Cooling water | Entry | / | DN65 | DN65 | DN65 |

| Consumption | Kg/cycle | 55-150 | 55-180 | 60-190 | |

| Pressure | MPa | 0.4 | 0.4 | 0.4 | |

| Compressed air | Entry | / | DN50 | DN50 | DN50 |

| Consumption | m3/cycle | 1.5 | 1.5 | 1.4 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | |

| Vacuum Pump Capacity | m3/h | 230 | 280 | 280 | |

| Connected Load | Kw | 12.5 | 16.5 | 16.5 | |

| Overall Dimension | mm | 4600×2140 ×3100 | 5000×2300 ×3400 | 5000×2450 ×3500 | |

| Machine Weight | Kg | 5700 | 7000 | 7500 | |

| Cycle time/Packaging products | S | 50-90 | 70-100 | 70-110 | |

| items | Machine specification | |

| Anti-corrosion treatment | Machine body | Welded-heating treatment-sandblast-Zink coating-painting |

| All steam, water ,drainage pipe | Hot-zink coating | |

| Electrical element | Touch screen PLC | Mitsubishi PLC, |

| Relay, contactor | Schneider electric | |

| Approx-sensor | Autonics | |

| Air Solenoid Valve | Burket ,Germany | |

| Steam | Main DN100 | |

| DN65 for fixed and movable size | ||

| With by-pass steam pipe, DN40 | ||

| Electrical proportional steam pressure setting in touch screen | ||

| GP1000 PRV | ||

| Cooling water | DN65 | |

| Mold cooling &vacuum cooling | ||

| Compressed air de-mould | Multi-selection mold | |

| M1 &M1 , electrical proportional pressure control | ||

| Filling hopper | 2-Vertical type | |

| 44-1″ outlet | ||

| Pressurized tank filling | ||

| Fast connector equipped | ||

| Blowing filling pressure adjustable by mechanical proportional control | ||

| High machine leg | 1.5 meter higher machine leg , Hot GV |

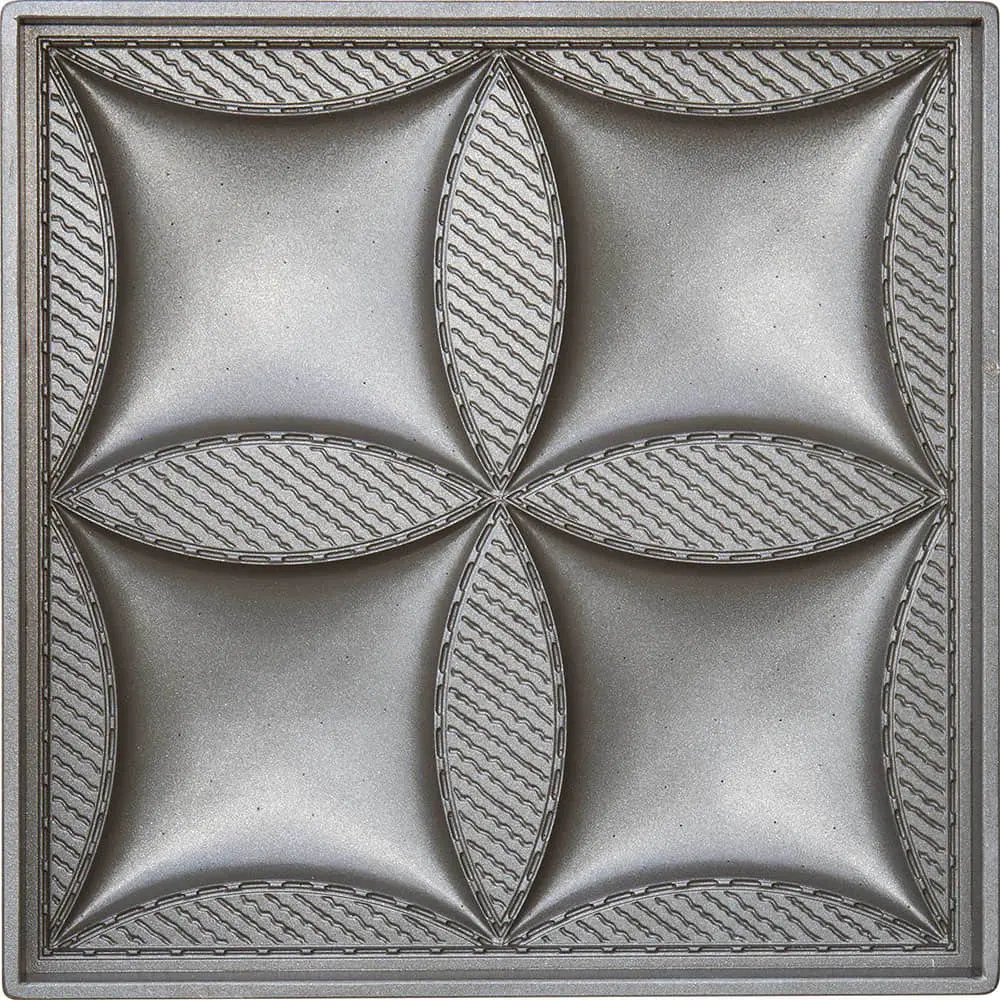

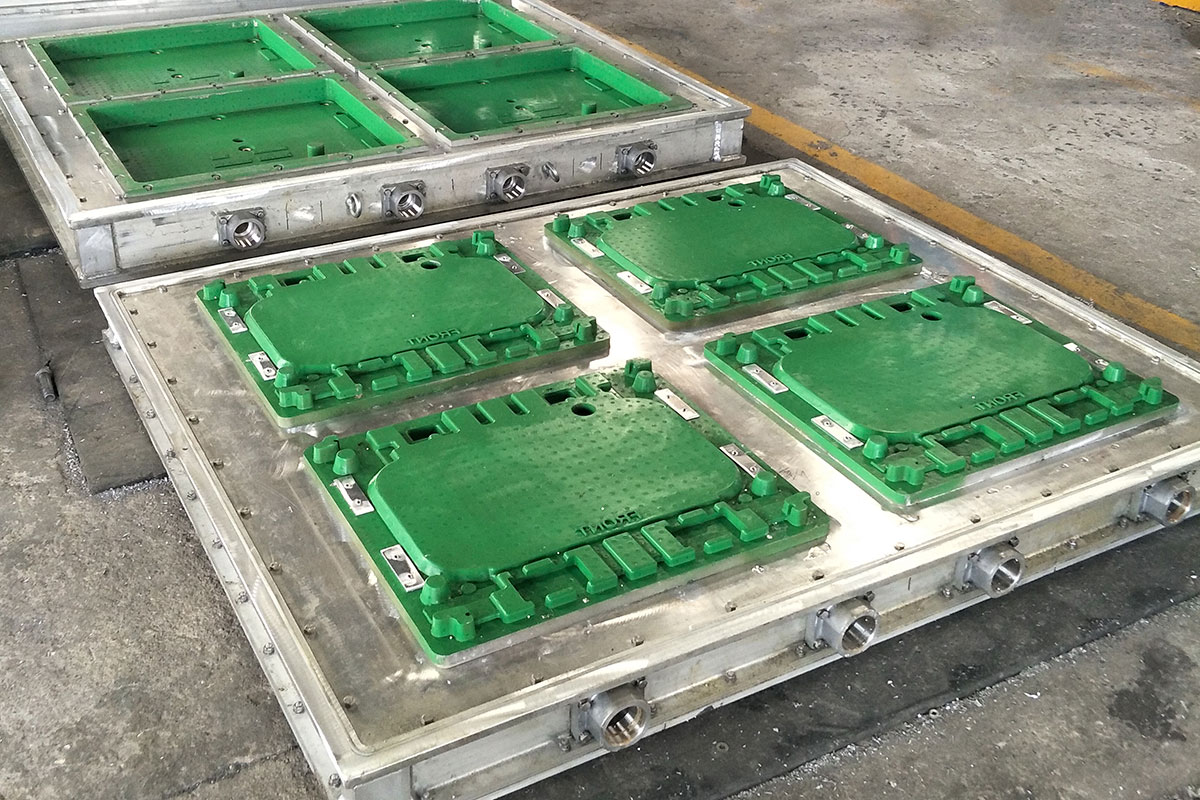

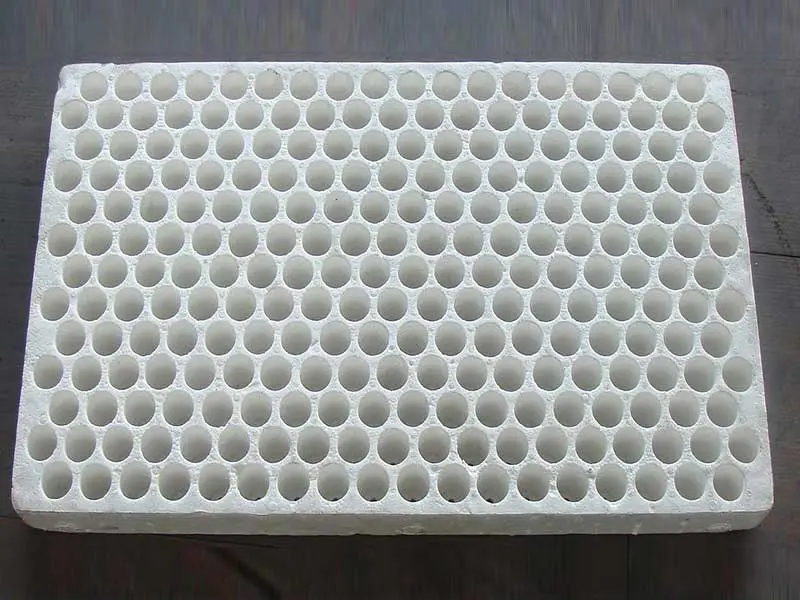

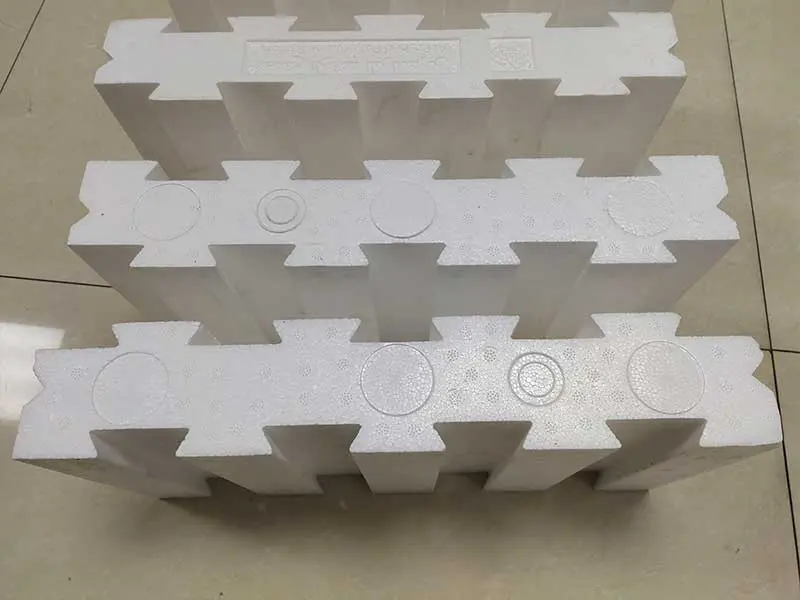

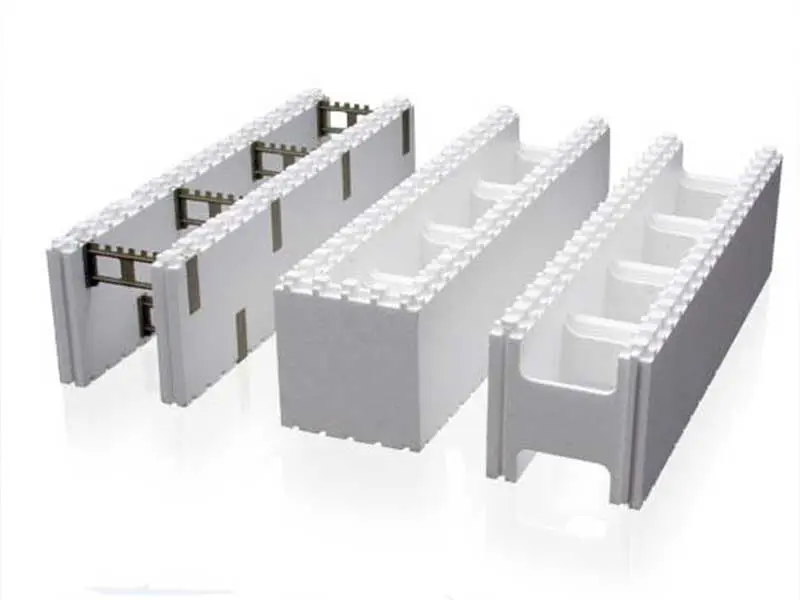

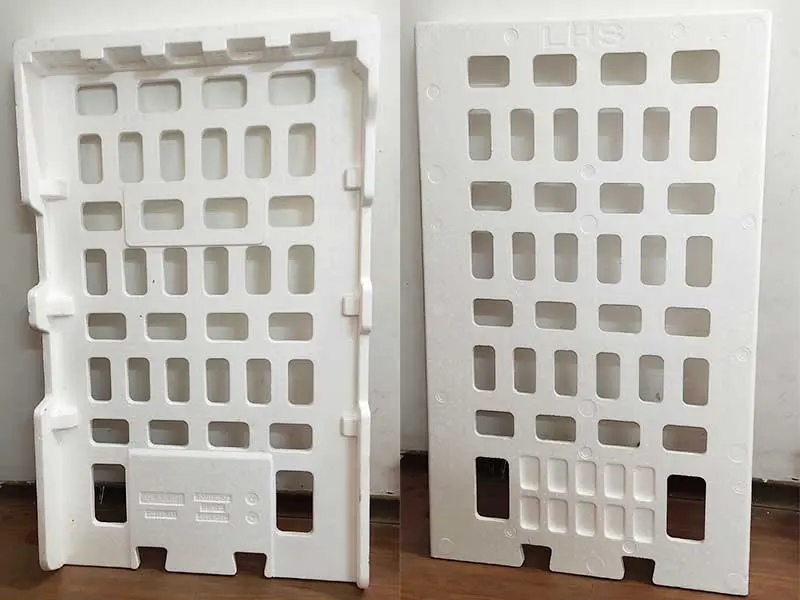

Our Moulds

Application

EPS is commonly used for packaging medical,fruit,vegetables and electrical, insulation panels for building. With the good quality,it can be expand 40 times the volume of the original polystyrene bead.

Leave Your Message

For more information about any of our services, don’t hesitate to get in touch. Our team is always happy to provide information about EPS Industry products.