Whole process: EPS Beads–pre-expander –silo–block molding machine–cutting machine –EPS sheets or profile

Auxiliary equipment: Steam boiler and accumulator , Air compressor and Air receiver , water cooling tower and pumps

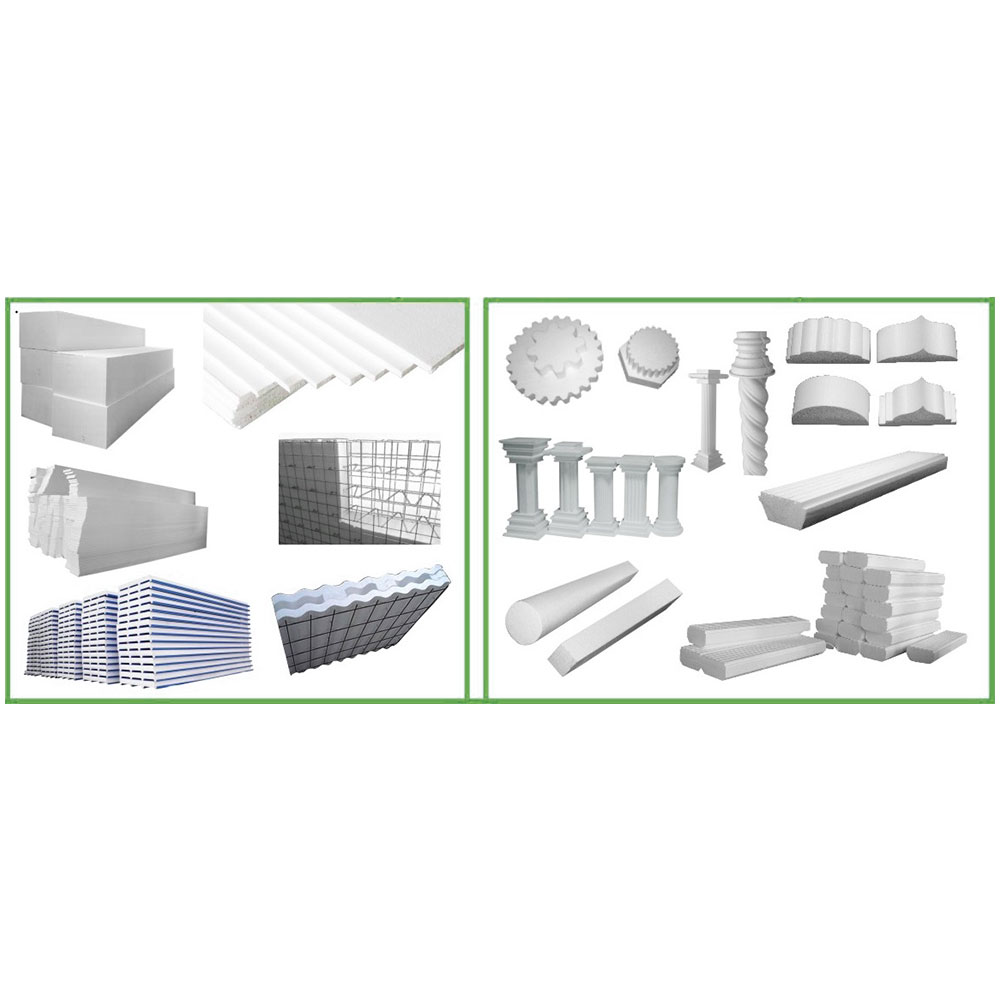

EPS block molding Application: EPS sheet for insulation / EPS element for construction / EPS profile for decoration

Daily 300 cubic Meter EPS Block Production Line list:

| 1 | BATCH PRE-EXPANDER SPJ150B Density :8-30g/l | 1unit |

| 2 | EPS BLOCK MOLDING MACHINE SPB400 WITH VACUUM SYSTEM LENGTH Length 4m x 1.2 mx 1m | 1unit |

| 3 | CUTTING MACHINE SPC400 | 1units |

| 4 | Re-Cycling Machine | 1unit |

| B | Auxiliary Equipment | |

| 5 | SILO(Semi-Auto) SYSTEM | 20units |

| 6 | AIR COMPRESSOR 3.6m3/min, 7 bar | 1unit |

| 7 | COMPRESSED AIR TANK WITH ACCESSARY 2 m2 | 1unit |

| 8 | STEAM ACCUMULATOR 12m3 volumn | 1unit |

| 9 | COOLING WATER PUMP,COOLING TOWER 50m3/hour , as well as 7.5kw pump. | unit |

| 10 | STEAM BOILER 2 tons per hour , 1Mpa | 1unit |