Introduction

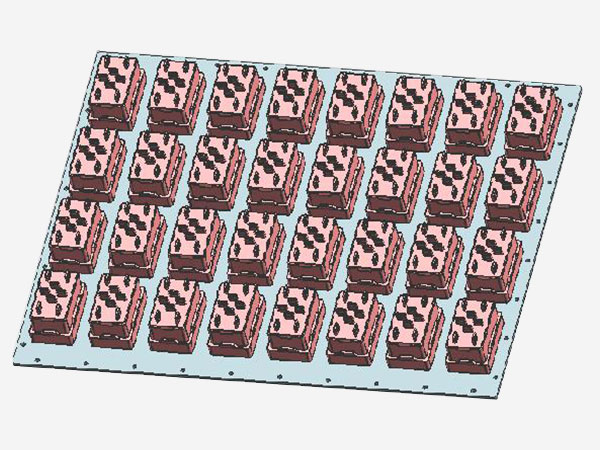

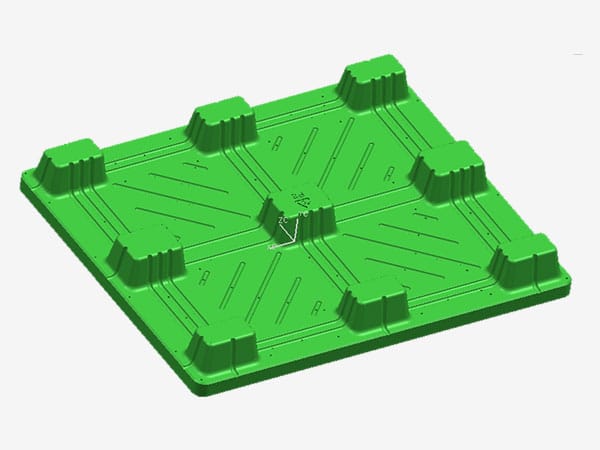

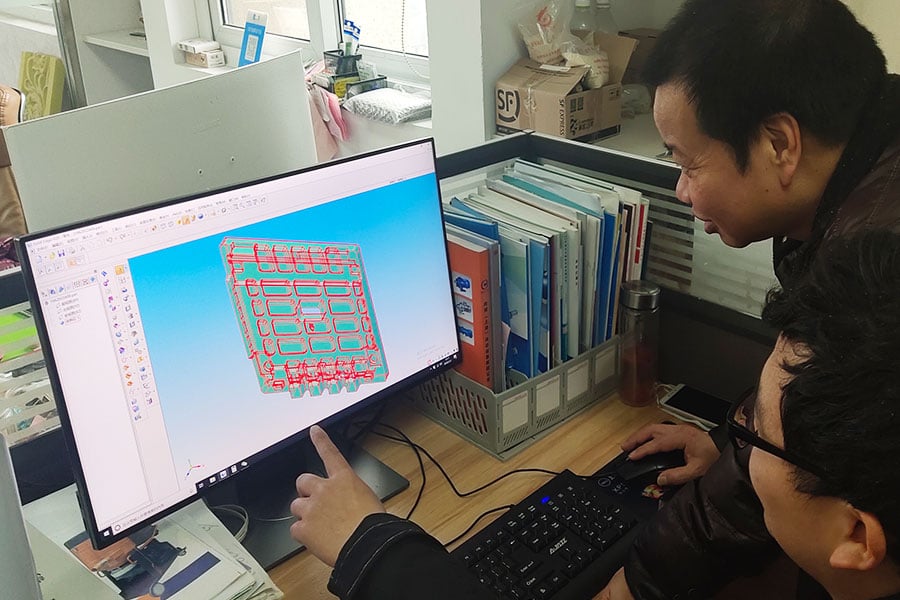

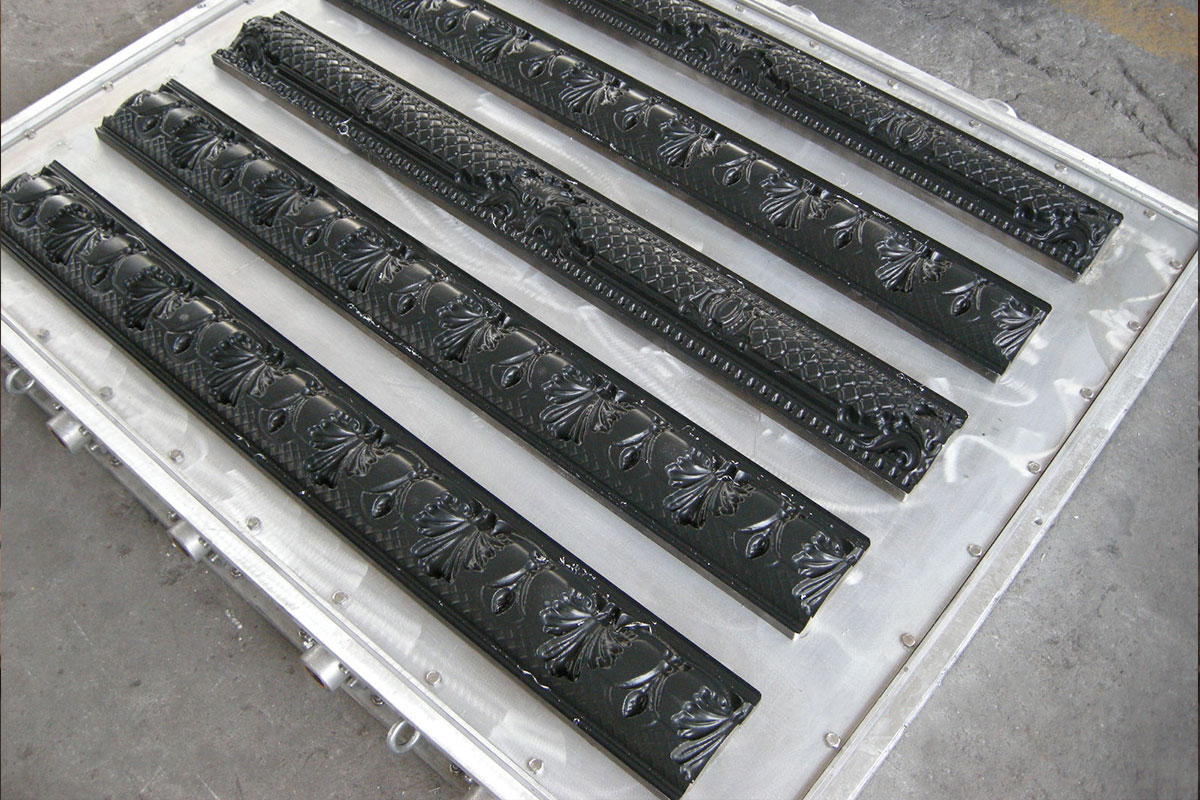

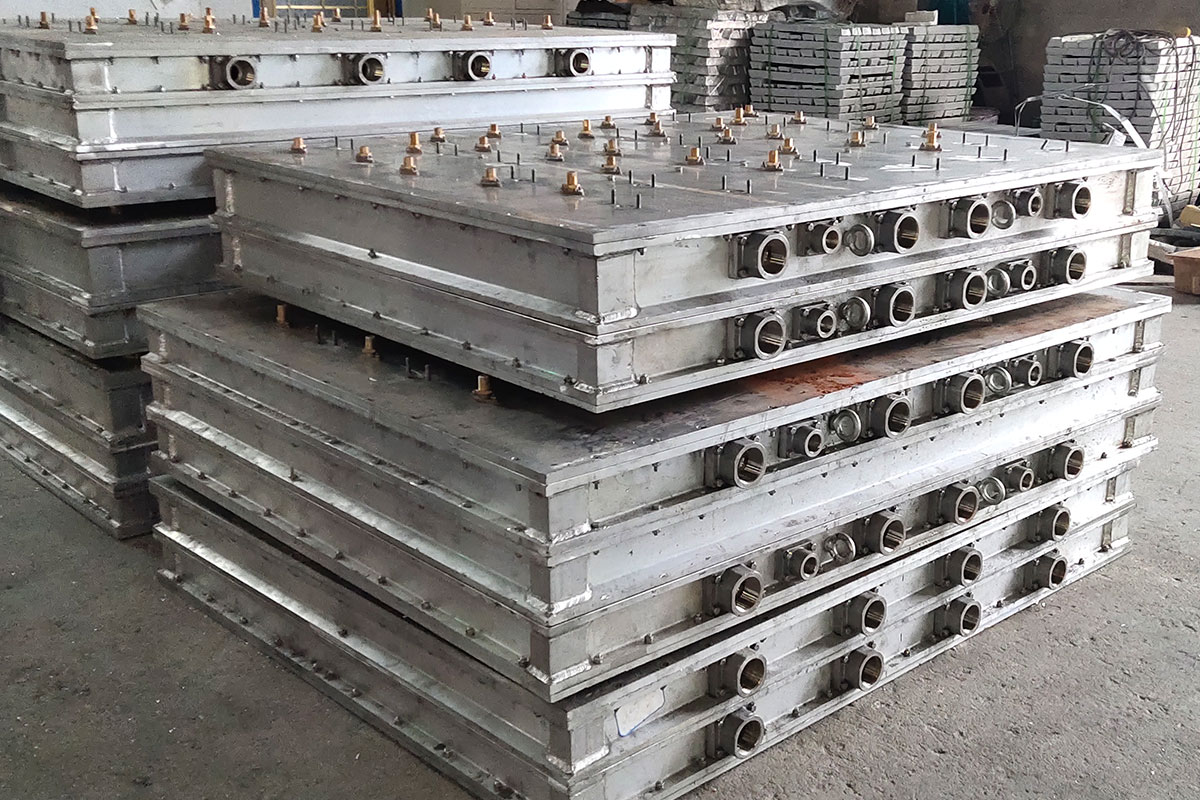

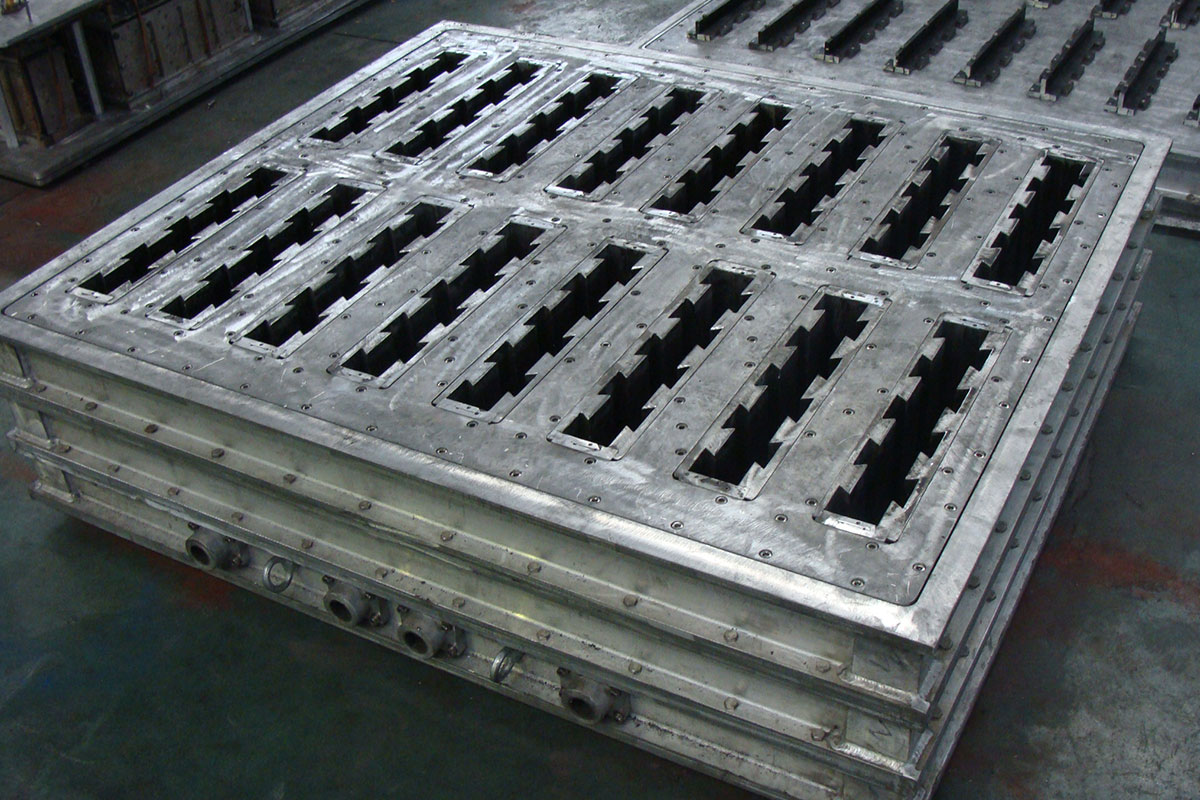

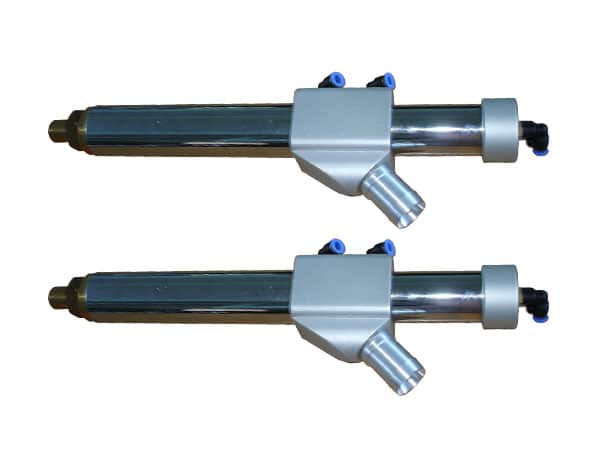

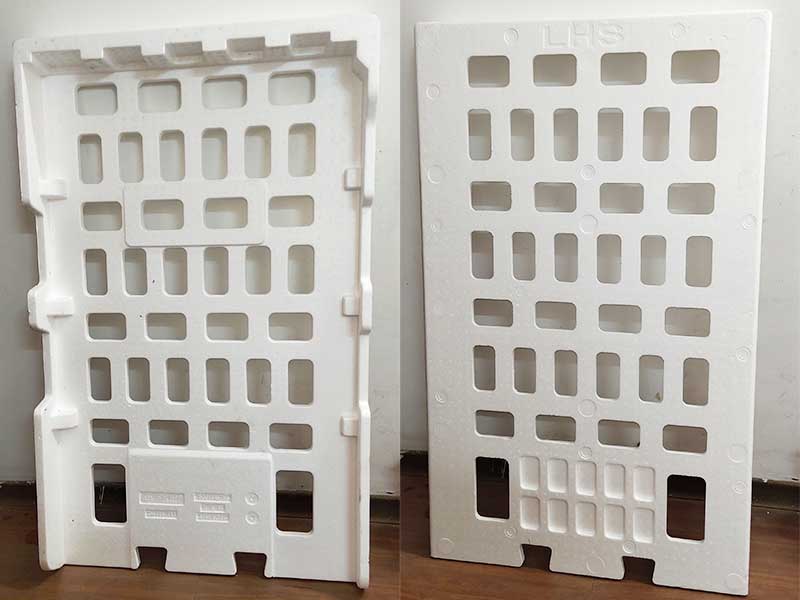

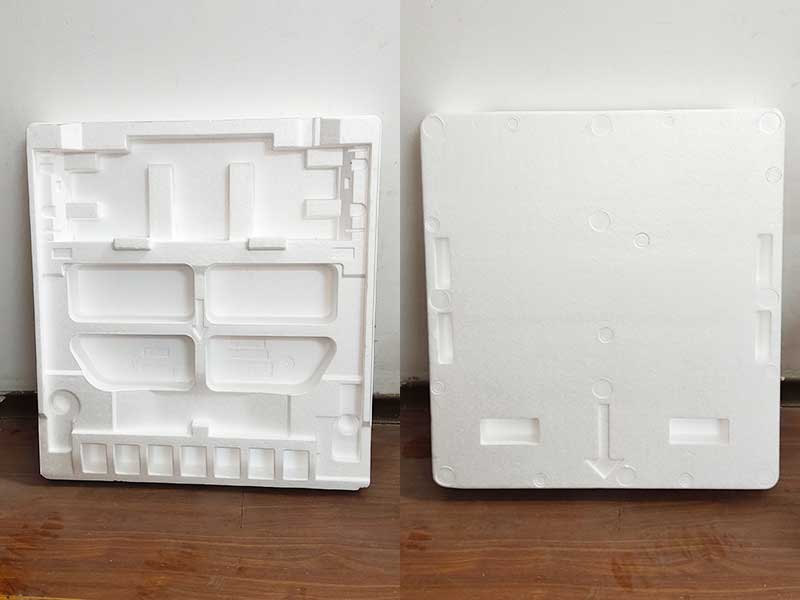

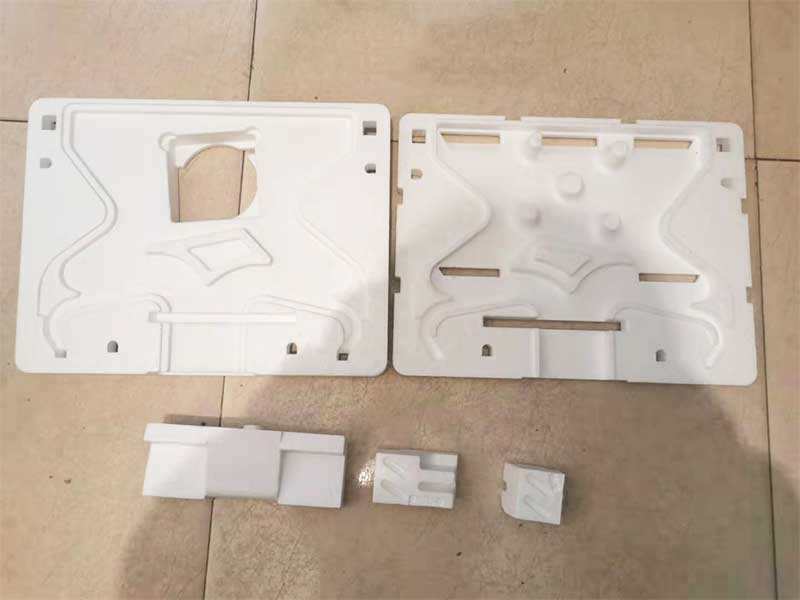

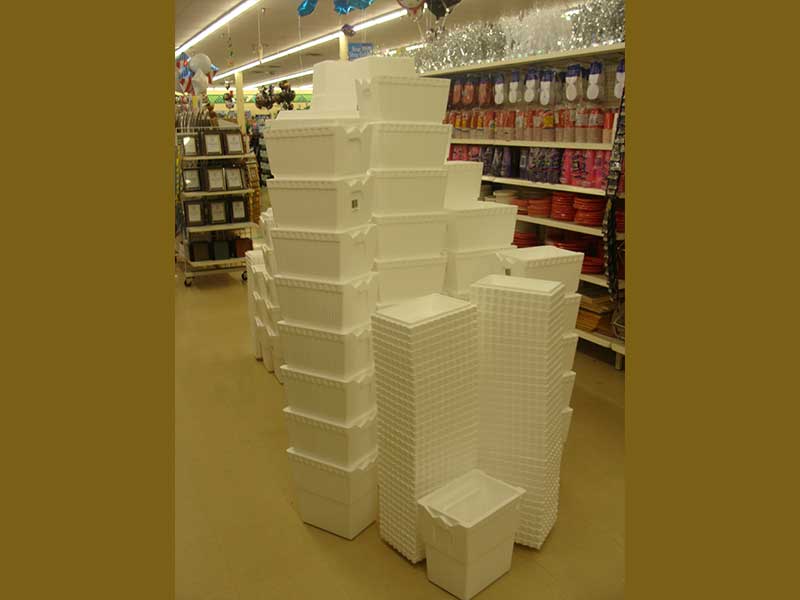

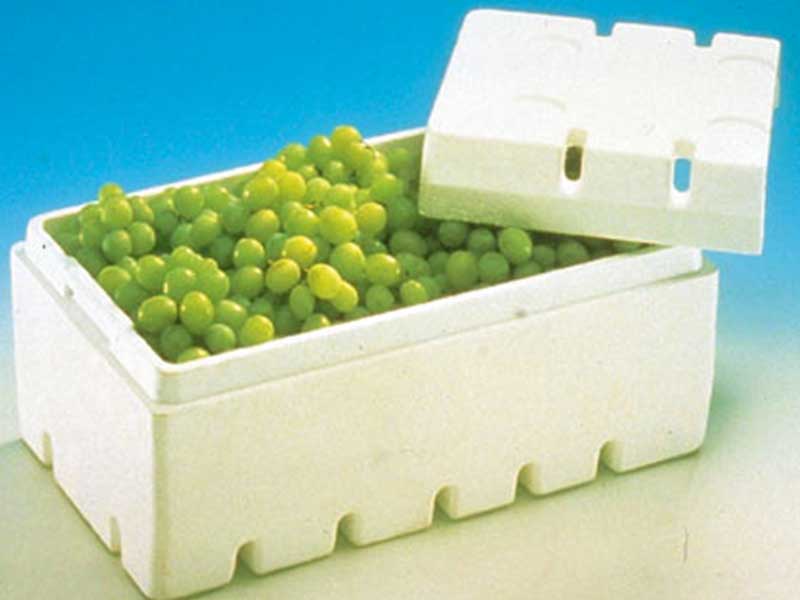

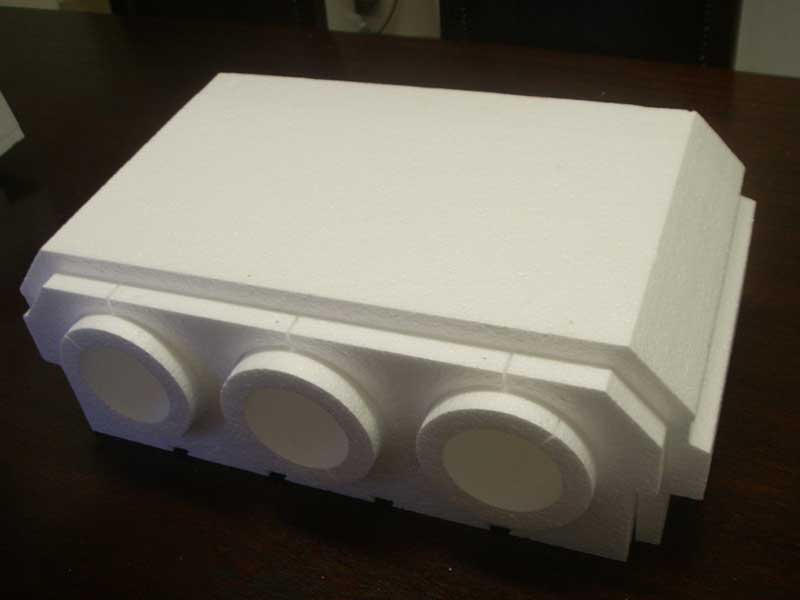

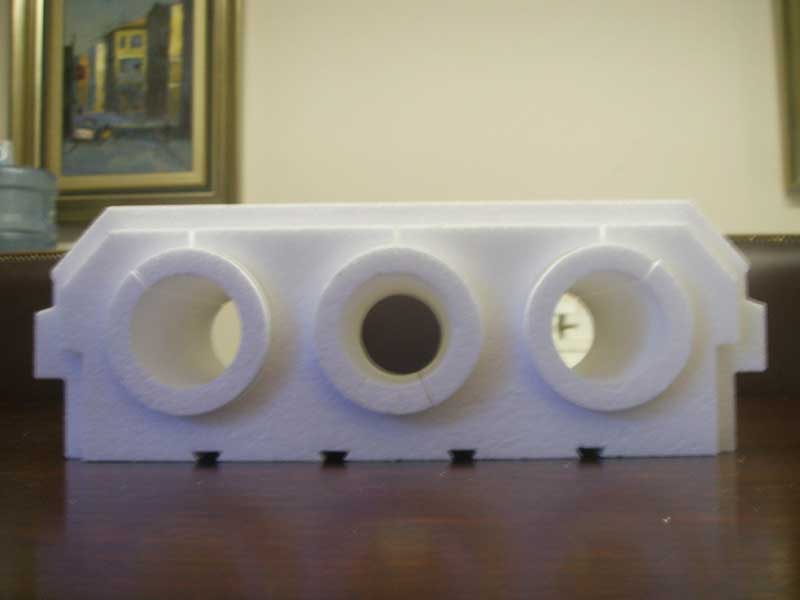

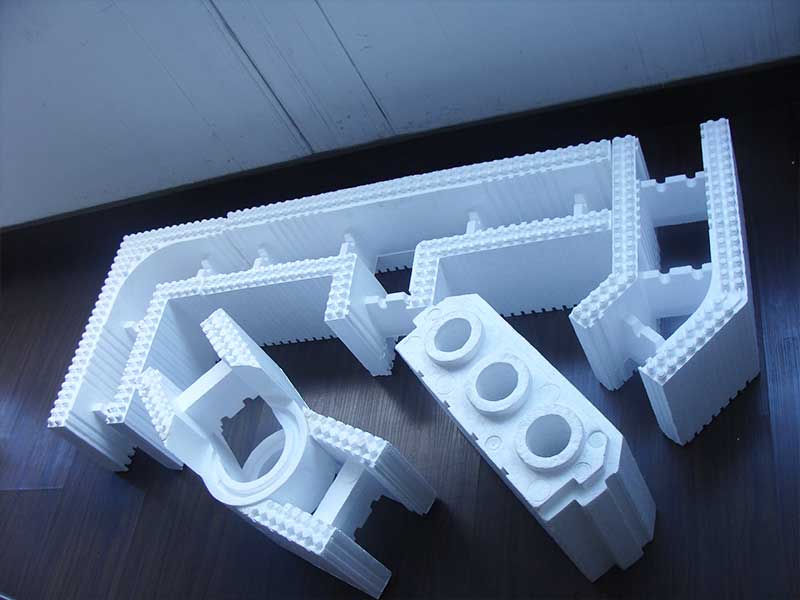

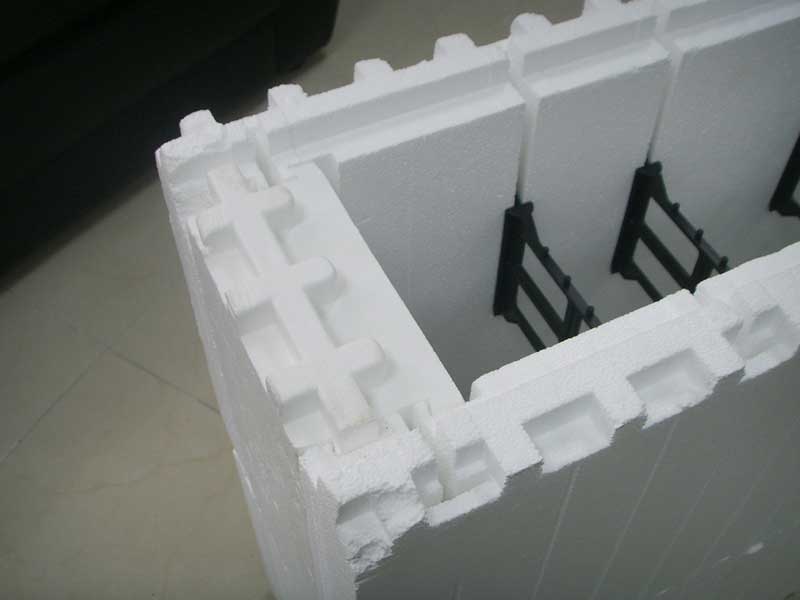

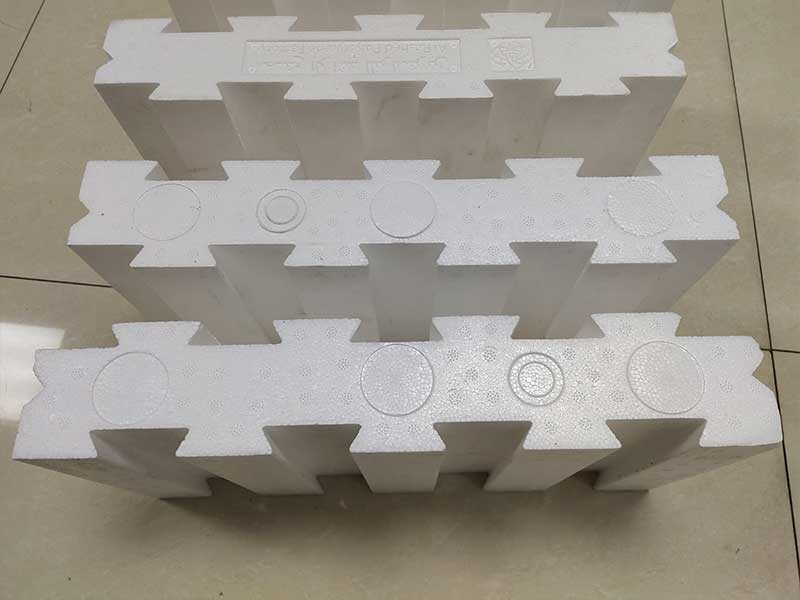

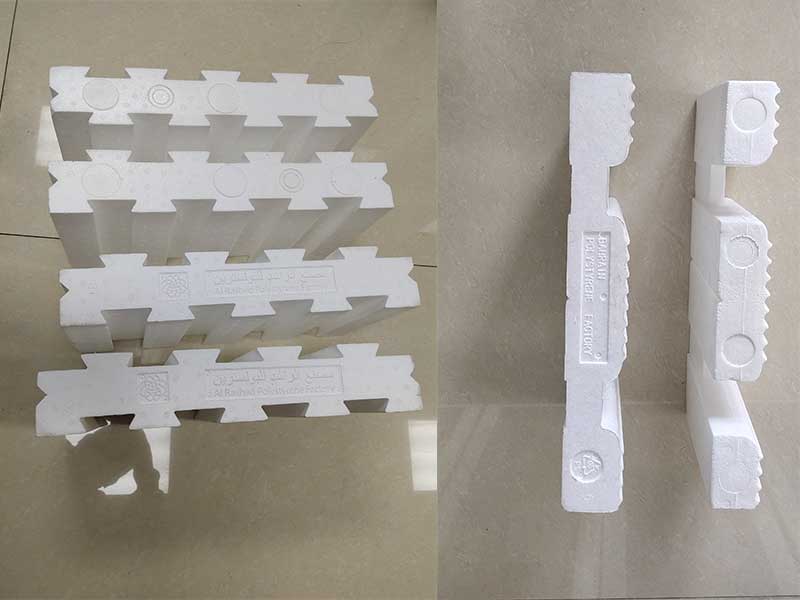

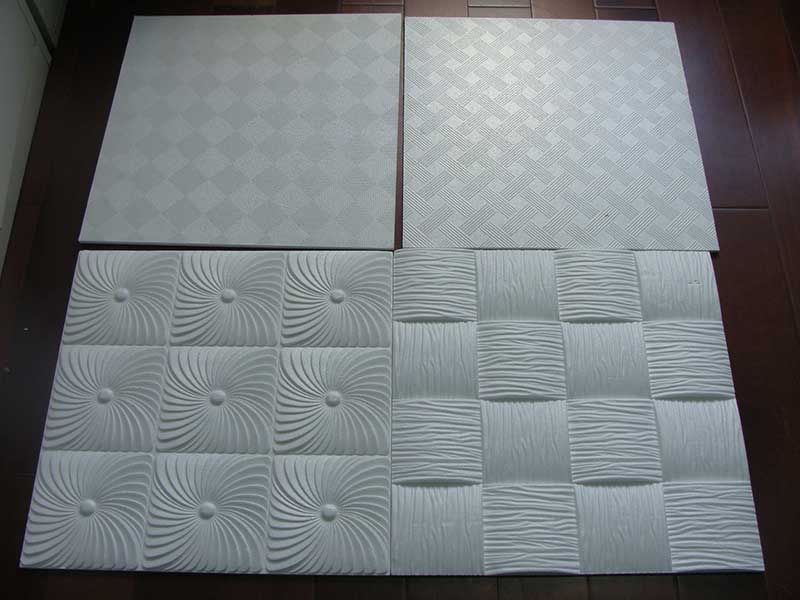

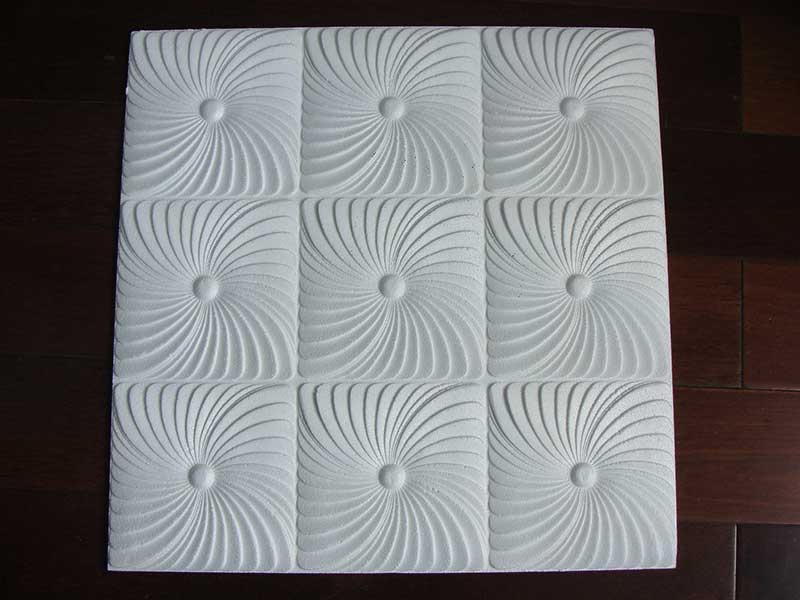

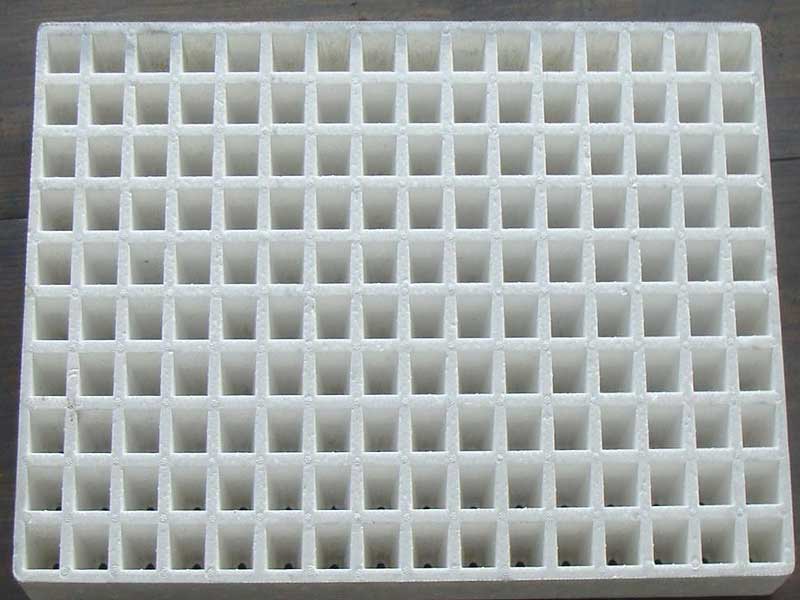

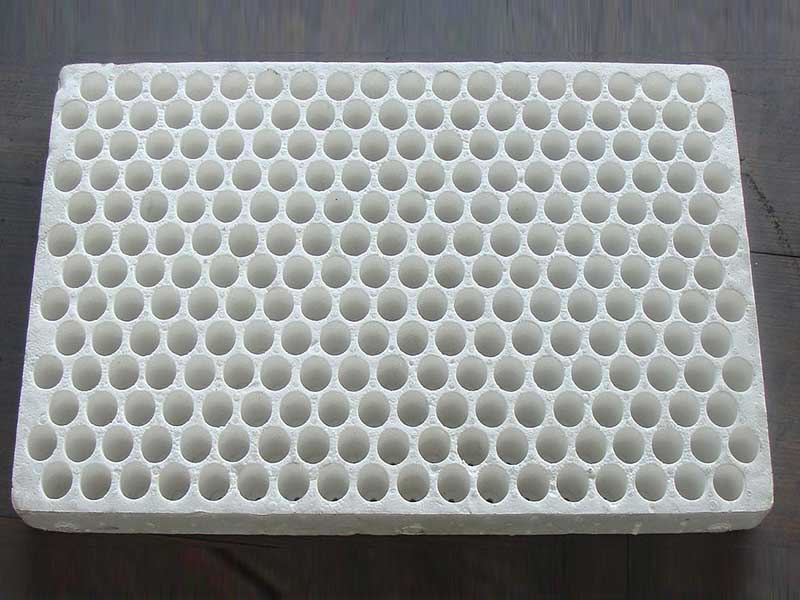

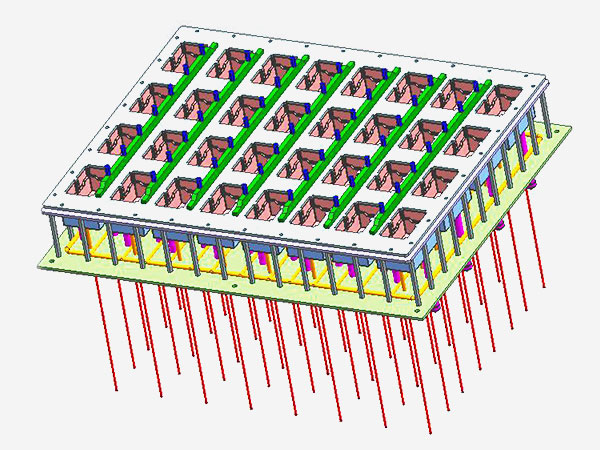

With strong technical force and advanced production and processing equipment, the company provides domestic and foreign customers with the services of designing and manufacturing various foam molds. The main products are widely used in electrical industry, aquaculture industry, agricultural industry, construction industry, foundry machinery industry, etc …